Let's do a comparison of 3 Cornell Pump Curves:

4414 - 4 inch outflow, 4 inch intake, 14 inch impeller

4514 - 4 inch outflow, 5 inch intake, 14 inch impeller

4NHTB - 4 inch outflow, 5 inch intake, 17 inch impeller

I know it's bad to start with a disclaimer, but please realize these numbers are found using WATER, AT SEA LEVEL. ESTIMATIONS HAVE BEEN MADE. This is simply an exercise in reading pump curves.

***NOT GUIDELINES OF HOW TO PLACE PUMPS.***

Below is the curve for the 4414 Pump. Notice the US. GALLONS PER MINUTE across the bottom. The last number listed is 1600 GPM. Follow the 1600 line straight up, and it says if you run this pump at 2300 RPM, you could achieve 320 FT of TOTAL DYNAMIC HEAD. The pump is running at about 77.5% efficiency way out there in the top right corner (almost the best efficiency this pump can run). But it has to be fed (at an almost impossible amount to be a lead pump at this GPM). The NPSH (net positive suction head) is greater than 24 ft. -- I'm estimating closer to 30 ft. or more to keep it from cavitation.

On flat terrain, wishing to travel 1 mile, and wishing to use 4414 pumps to get there, we will use 6" mainline hose, with a Head loss at 1600 GPM to be about 90 FT per 660 FT. length of hose.

320ft of TDH leaving pump 1. Pump 2 will need 30 ft NPSH to keep from cavitation.

320' ÷ 90' (Head loss) = 3.55 lengths of hose

3 lengths x 90' = 270' of TDH used

320' - 270' = 50' of TDH remaining

Pump 1 (with it's NPSH fulfilled), 3 lengths of 6" hose, Pump 2, 3 lengths of 6" hose, Pump 3, you get the idea.

Lets say you drop into 5 inch drags after the last 4414 pump. Head loss jumps to 200' per 660ft length. No NPSH required to the applicator so:

320' ÷ 200' = 1.6 lengths of drags

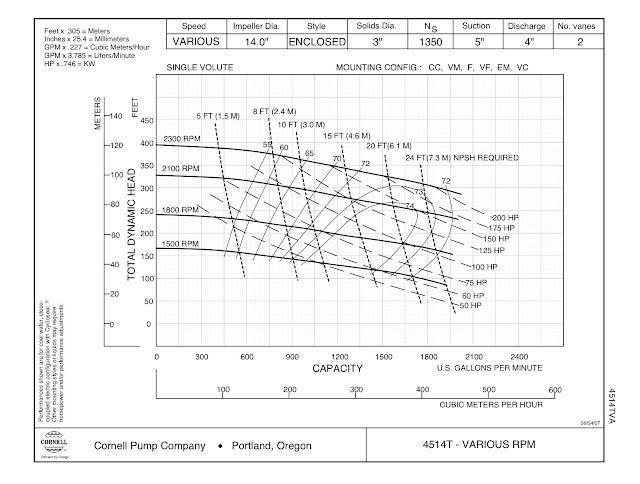

BELOW -- 4514 Cornell Pump Curve

The top right corner of this curve ends right around 1950 GPM, at 2300 RPM, with about 30' NPSH

required, providing 290ft. of TDH.

Again - 4514 Pumps in line with 6" mainline hose on flat terrain.

At 1950 GPM - Head loss in 6" hose is about 130' ft.

290' TDH ÷ 130' = 2.23 lengths of hose

2 x 130' = 260' TDH used

290' - 260' = 30 ft. TDH remaining to fulfill NPSH Requirements for the next pump.

SO: Pump 1, 2 lengths of hose, Pump 2, 2 lengths of hose, Pump 3, 2 lengths of hose, Pump 4, 2 lengths of hose -- this is silly...

Lets try this 4514 at 1500 GPM, still 2300 RPM, still in the 72% efficiency with less NPSH Required (19') and more TDH (330 ft). Head loss is less, at 1500 GPM is 80ft.

330' ÷ 80' = 4.125 lengths of hose

4 x 80' = 320' of TDH used

330' - 320' = 10 ft remaining -- NOT ENOUGH - 19 ft is needed for the next unit.

How about 3 lengths?

3 x 80' = 240'

330' - 240' = 90 ft remaining

So: Pump 1, 3 lengths of hose, Pump 2, 3 lengths of hose, Pump 3, 3 lengths of hose....

BELOW: 4NHTB Cornell Pump Curve

With this pump we're going to follow the 1875 GPM line up and meet 2000 RPM and receive 390 ft of TDH. NPSH Required is estimated at about 25' - 27'.

Head loss at this flow through 6" mainline is about 120 ft. So:

390' ÷ 120' = 3.25 lengths

3 x 120 = 360' used

390' - 360' = 30' remaining (25' to 27' needed)

Head loss through 8" mainline at this rate is about 51 ft.

390' ÷ 51' = 7.647 lengths

7 x 51' = 357' used

390' - 357' = 33' remaining (25' to 27' needed)

6" hose:

Pump 1, 3 lengths of hose, Pump 2, 3 lengths of hose, Pump 3,

**Head loss through 5" drags at 1875 GPM is about 285 ft. - giving you 1.368 lengths to the tractor

8" hose:

Pump 1, 7 lengths of hose, Pump 2, 3 lengths of 6" - mainline/drags

Theses are very basic and incomplete examples. Estimates were made on Head loss through the hose. Estimates were made on NPSH Required. Terrain, elevation, and temperature were not considered. MANURE WAS NOT CONSIDERED.

Efficiencies of the Engine matched to run the pump was not considered. These examples do not show how PCE puts pump/engine units together nor how PCE would utilize these pumps.

If you'd like to go back through and see all these pumps at 1000 GPM, just use 38 ft. of Head Loss per 660 ft. of 6" hose. The distances improve.

Thanks,

Nancy